As cities and urban spaces continue to grow, space for construction work has become increasingly limited. More and more would-be constructors are using machinery that is versatile and operable in congested spaces. Using the right construction machine improves efficiency, productivity and it can reduce hazards.

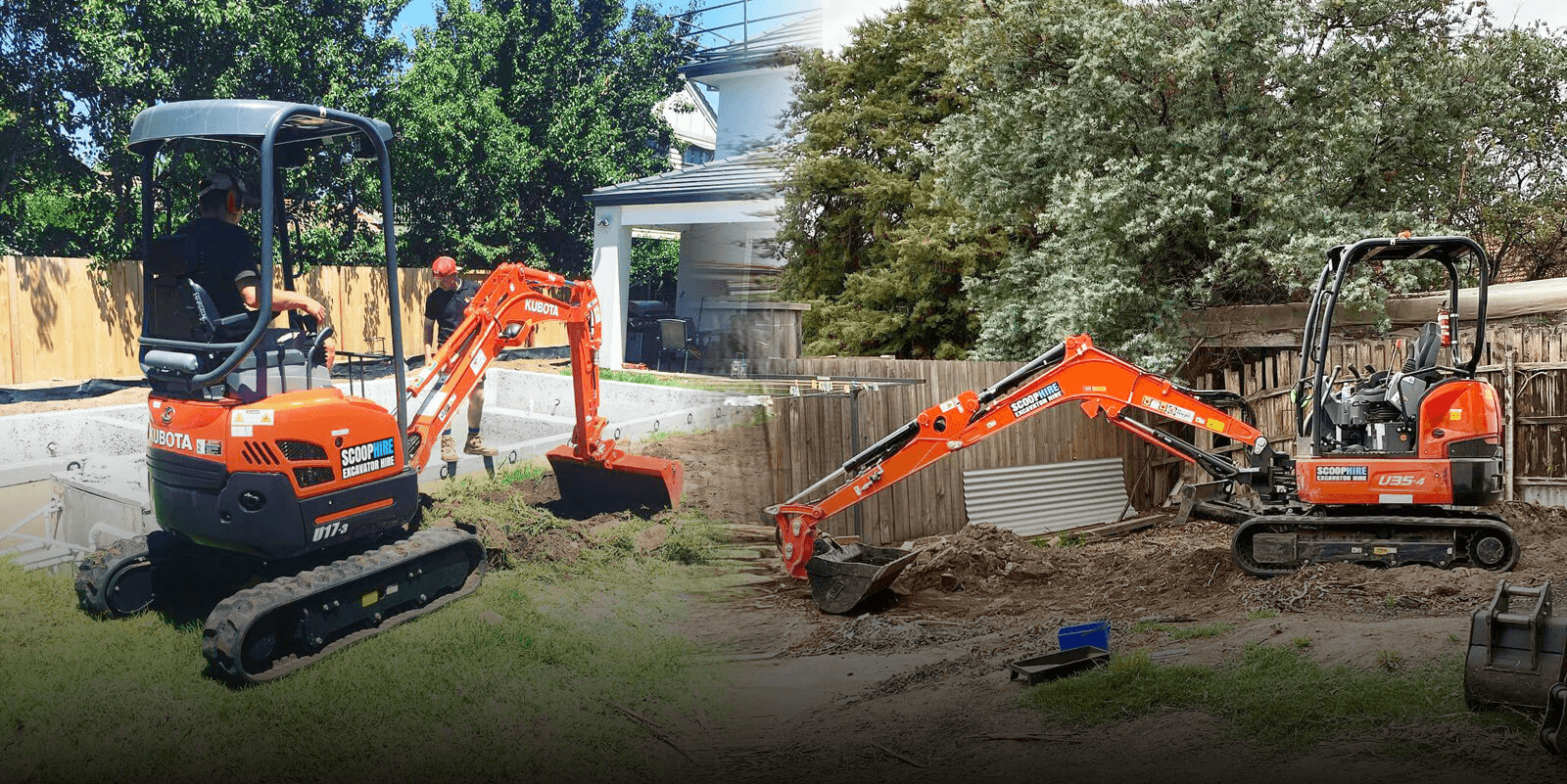

An excavator is an important piece of heavy machinery that is used in most construction companies. Excavators are also referred to as diggers. These machines are used for a variety of jobs such as digging, landscaping, demolition, dredging, money, etc. They come in different sizes and different configurations.

Excavator hire machinery is basically made up of a boom, a dipper and a bucket. These three standard pieces are connected to a cab that is placed on top of a rotating house. These pieces of equipment either have wheels or run on tracks depending on the type of projects that are being used for.

Excavators come in a variety of sizes. They can be adapted by swapping the primary component- the bucket with an auger to dig holes, a hammer for knocking down concrete or breaking up rocks, rippers, rakes, compactors and other attachments. All of this make excavators true multi-purpose equipment.

Besides the different attachments, medium to large excavators have different configurations. You get excavators with conventional tailswings and zero tail swing.

What makes these two configurations different?

Conventional Tailswing

The rear of the upper structure of a conventional tailswing excavator has a counterweight that extends a couple of inches past the tracks. This gives it a longer tail swing radius and more leverage. This type of excavator has a longer operating dimension; it provides comfort and improves productivity.

The key benefits of a Conventional tailswing include:

- Greater lifting capacity because of where the counterweight is positioned.

- The bucket has a greater digging force.

- These Excavators have a bigger cabin size.

- These excavators are robust and perform well under difficult open environments.

- The conventional tailswing excavator is cheaper

Conventional tailswing machines are designed for general applications where space is not a problem.

Zero tailswing

As the name suggests, the zero swing excavator has a counterweight that does not extend past the tracks. This means that the rear part of the machine is always within the length of the tracks.

Zero tailswing machines compensate for the small length with more weight out back. They lift like their counterparts in front but are even better at lifting over the sides.

Zero tailswing excavators are popular these days because they are easy to move in urban and residential areas where space is restricted. The radius of the counterweight decreases the chance of property damage when work takes place next to buildings or any other obstruction.

The key benefits of a Zero tailswing machine include:

- Easy to use on tight spaces. This class of excavators is popularly used in road maintenance. It makes it possible for the closure of one lane to enable the project to continue instead of closing two or more lanes as it usually happens when a conventional swing excavator is used.

- Zero swing machines offer a reduced probability of being hazards within the environment they are located in because of the short turns it makes.

- Zero tailswings have an engine, a hydraulic system that moves the boom, the arm and other attachments.

- Zero swing excavators are easy to transport.

Bottom line

Both these configurations have operational and productivity advantages depending on the operational environment.